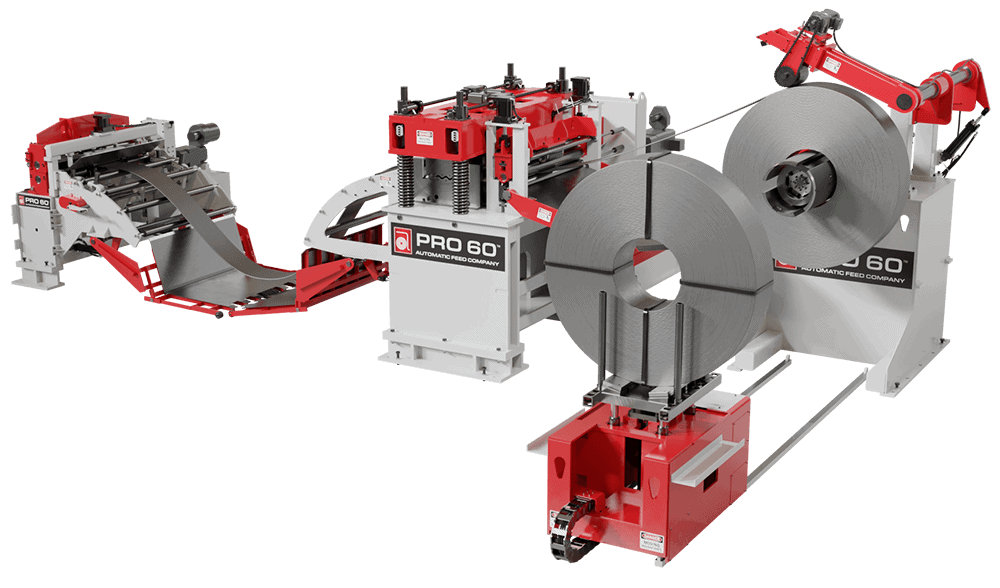

We’ve taken our high strength steel and aluminum processing experience and packaged it into our new and compact PRO Series coil lines. These systems are designed for feeding coil directly into a blanking or stamping press, shear or laser cell.

The PRO Series is available in three sizes perfectly suited for Tier suppliers who are processing UHSS, AHSS and/or aluminum for applications such as inner body panels and stamped parts. The PRO name says it all — our PRO 40 processes coil up to 40″ wide, the PRO 60, up to 60″ wide and the PRO 80, up to 80″ wide.

These new lines are available in three standard widths – 40”, 60”, and 80” inches, designated as PRO 40, PRO 60, and PRO 80.

| General | PRO SERIES 40 | PRO SERIES 60 | PRO SERIES 80 |

|---|---|---|---|

| Maximum Coil Weight | 27.25 metric ton (60,000 lbs) | 27.25 metric ton (60,000 lbs) | 27.25 metric ton (60,000 lbs) |

| Material Thickness | 0.5 mm – 6.4 mm (0.020” – 0.25”) | 0.5 mm – 6.4 mm (0.020” – 0.25”) | 0.5 mm – 6.4 mm (0.020” – 0.25”) |

| Coil Width | 100 mm – 1016 mm (4” – 40”) | 100mm – 1525mm (4”–60”) | 100mm – 2032mm (4”-80”) |

| Coil Outside Diameter | 762 mm – 2032 mm (30” – 80”) | 762 mm – 2032 mm (30” – 80”) | 762 mm – 2032 mm (30” – 80”) |

| Coil Inside Diameter | 508 mm – 610 mm (18” – 24”) | 508 mm – 610 mm (18” – 24”) | 508 mm – 610 mm (18” – 24”) |

| Line Direction | Customer Specified | Customer Specified | Customer Specified |

| Feed Passline Height | Customer Specified | Customer Specified | Customer Specified |

| Material Thickness | PRO SERIES 40 | PRO SERIES 60 | PRO SERIES 80 |

|---|---|---|---|

| Steel | 0.5 mm – 6.4 mm | 0.5 mm – 6.4 mm | 0.5 mm – 6.4 mm |

| Steel | 0.020” – 0.25 | 0.020” – 0.25 | 0.020” – 0.25 |

| Aluminum | 0.5 mm – 6.4 mm | 0.5 mm – 6.4 mm | 0.5 mm – 6.4 mm |

| Aluminum | 0.020” – 0.25” | 0.020” – 0.25 | 0.020” – 0.25 |

| Material Width Range (MM) | PRO SERIES 40 | PRO SERIES 60 | PRO SERIES 80 |

|---|---|---|---|

| Steel | 100 mm – 1016 mm | 100 mm – 1525 mm | 100 mm – 2032 mm |

| Steel | 4” – 40” | 4" – 60" | 4" – 80" |

| Aluminum | 100 mm – 1016 mm | 100 mm – 1525 mm | 100 mm – 2032 mm |

| Aluminum | 4” – 40” | 4" – 60" | 4" – 80" |

| Material Yield MPA | PRO SERIES 40 | PRO SERIES 60 | PRO SERIES 80 |

|---|---|---|---|

| Steel | 120 – 1200 MPa | 120 – 1200 MPa | 120 – 1200 MPa |

| Steel | 17.4 – 174 ksi | 17.4 – 174 ksi | 17.4 – 174 ksi |

| Aluminum | 50 – 350 MPa | 50 – 350 MPa | 50 – 350 MPa |

| Aluminum | 7.25 – 50.8 ksi | 7.25 – 50.8 ksi | 7.25 – 50.8 ksi |

| Production Speed | PRO SERIES 40 | PRO SERIES 60 | PRO SERIES 80 |

|---|---|---|---|

| Max Line Speed | 50 mpm (164 FPM) | 50 mpm (164 FPM) | 50 mpm (164 FPM) |

For the past few decades, Automatic Feed (AFCO) has primarily been recognized for providing automotive OEMs and Tier 1 suppliers with automated, high-speed blanking, cut-to-length and laser blanking lines for surface-critical applications. What may not be as well-known is that fact that for over 70 years, AFCO has also been supplying lines to the appliance, agriculture, truck and heavy construction industries, specializing in heavy gauge and high-strength steels.

While the OEMs still maintain much of their stamping in house, they rely heavily on Tier suppliers for much of the inner body blanks and progressive die stampings. With the new PRO Series coil feed lines, AFCO brings expertise for processing high strength steel and aluminum to the Tier stamping market.